Blog

Cold Peel vs Hot Peel for DTF Transfers: How They Work and Which One to Choose

When working with DTF transfers, understanding the difference between cold peel vs hot peel is key to getting the best results. Why? – Because these two peeling methods play a big role in how well your transfer sticks and how the final design looks.

In this article, we at CustomAny will break down the fundamentals of cold peel vs hot peel, how each peel method works, as well as their pros and cons. By learning these differences, you can decide which one is the most suitable choice for your DTF transfer needs.

Learning Cold Peel vs Hot Peel DTF Transfers

The time you peel the film layer from applied DTF transfer can significantly impact the quality, durability, and look of your finished design. To get it right, you need to clarify whether the iron-on transfers you are using are cold peel or hot peel. This leads us to the “cold peel vs hot peel” discussion.

In fact, what determines whether your DTF transfer is cold peel or hot peel is the type of transfer film used, which is directly linked to the structure of the transfer film.

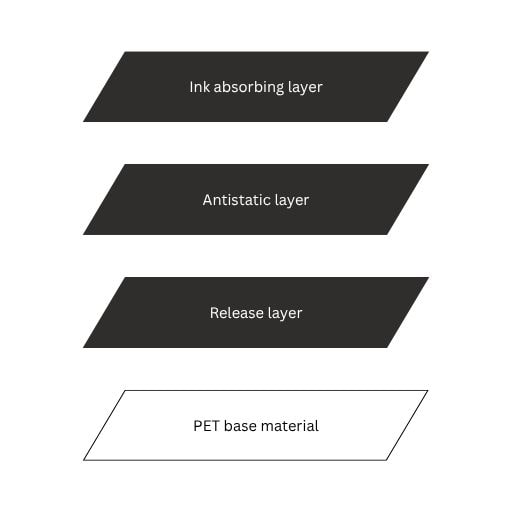

1. Transfer film structure:

Specifically, only the DTF film layer of a DTF transfer alone is made up of several layers:

- An ink receptive layer (where the ink is printed on)

- An antistatic layer

- A release layer

- A PET base material.

The type of the release layer is what determines whether a transfer is hot peel or cold peel:

- Hot peel transfers use a wax-based release layer, which allows the film to be peeled away just seconds after heat pressing while it is still warm.

- Cold peel transfers use a silicone-based release layer, which requires the film to cool down completely before it can be removed.

Now that we know which determines one DTF transfer is hot peel or cold peel, let’s go into detailed features of each peeling option.

2. What Is a Cold Peel DTF Transfer?

Cold peel transfers are DTF transfer pieces that require a waiting time period until it has completely cooled before peeling. It means, the time for cooling is the time for the adhesive layer fully sets, making the printed design firmly bonds to the fabric surface.

The cold peel method is especially helpful when working with complex artwork because it gives the adhesive extra time to bond well. This slow curing process creates a strong and durable finish that lasts through multiple washes and wears.

Pros of cold peel DTF transfers:

- The strong bonding results from this cold peel method helps reduce the risk of ink lifting or improper adhesion throughout and after the peeling step.

- It’s ideal for intricate or detailed designs where precision is important.

Cons of using cold peel transfers:

- It takes you more time for application because you need to wait for a cooling period.

- The finished surface of the item can feel slightly firmer or stiffer compared to hot peel transfers.

Thus, cold peel DTF transfers provide finishes that stay solid and resist lifting. However, it is less convenient for projects requiring speed or quick turnaround.

3. What Is a Hot Peel DTF Transfer?

Hot peel DTF transfers are iron-on products that have the film layer to peel off immediately after pressing, while it is still hot.

When peeled hot, their adhesive bonds quickly while still flexible. Peeling these hot peel DTF transfer films right after pressing helps the ink set smoothly into the fabric, leaving a softer and less glossy surface.

Hot peel DTF transfers’ Pros:

- Hot peels help you save time since it does not require any cooling wait.

- This method produces a softer, more flexible transfer result that feels comfortable on fabric.

Hot peel DTF transfers’ Cons:

- It demands fast and precise handling to avoid missing the perfect timing and causing damages.

- This method is not recommended for very detailed or fine designs because it is more likely to cause lifting details with the removed film layer.

In cases that speed matters most, such as in high-volume production or quick custom orders using DTF transfers, hot peel is a smart choice.

Understanding cold peel vs hot peel has gotten you the comprehensive vision before choosing the best method for your DTF projects. Cold peel offers a strong adhesion, especially for detailed and intricate designs, while hot peel saves time and creates a softer, more comfortable result on fabrics. Both have their pros and cons, so consider your design’s complexity and your workflow needs before choosing.

Cold Peel vs Hot Peel: Key Differences

When deciding between cold peel vs hot peel, let’s take time to break down their key differences. This step is essential for getting a clearer look on how each DTF transfer type performs: Each method affects how the print looks and feels, as well as how easy it is to handle.

| Criteria | Cold Peel | Hot Peel |

| Peel Timing | After cooling | Immediately hot |

| Speed | Slower | Faster |

| Print Feel | Firmer | Softer |

| Detail Handling | Better for fine details | Less suited for fine details |

| Risk of Peeling Issues | Lower risk | Higher risk |

This comparison table highlights how cold peel requires more time but offers stronger adhesion and better detail handling. On the other hand, hot peel is quicker and results in a softer print but needs careful timing and skill to avoid issues.

Choosing between cold peel vs hot peel is choosing the right product type and doing the suitable peel method. The final option depends on your priorities, whether it’s speed or precision.

To help you make a better decision, we simplify when you should choose cold peel or hot peel DTF transfers into recommended cases based on your needs. Let’s see how “cold peel vs hot peel” in the next sections.

When to Use Cold Peel DTF Transfers

Here are key situations where cold peel is the better option for your DTF transfer projects:

- You are working with complex designs: Cold peel ensures consistent, durable adhesion, making it ideal for your detailed artwork, whether it is a detailed graphic, gradient, or fine text. This type of DTF transfers allows even the smallest details to stay secure on the fabric surface after you peel off film.

- When maximum durability and minimal peeling risk are priorities in your project: The slower cooling allows your DTF transfers’ adhesive to fully set, creating a firmer, longer-lasting bond.

- You are applying DTF transfer onto stretchy or heat-sensitive fabrics: Waiting for the transfer to cool down before final impacts make sure the fabric surface stays still. This method gives the DTF transfer time to stay still and from a stable bond on unstable materials.

As one major outcome of mastering “cold peel vs hot peel” comparison, knowing you should use cold peel in these situations helps you achieve the best result in applying DTF transfers.

When to Use Hot Peel DTF Transfers

Choosing when to use hot peel DTF transfers depends on your production needs and fabric type. Here are the situations where we recommend using hot peel DTF transfers:

- You are working with simple, bold designs: Hot peels, which require quick handling, are a suitable option if you want to transfer simple prints onto fabric.

- You are an experienced user confident in applying DTF transfers: If you are familiar with this application process and confident in precise control, you can opt for hot peel iron-on transfers.

- You need quick production runs or large batches: Peeling the film layer immediately after pressing helps you speed up the process, making hot peel DTF transfers perfect for fast turnaround.

- You are applying DTF transfers onto heat-stable fabrics: Surfaces that are not stretchy or texture allow quick peeling without distortion or damage, so you can be confident to use hot peel transfers on such items.

When it comes to cold peel vs hot peel, these specific situations are the chances for you to use hot peel type, becoming more productive in applying DTF transfers.

Last words

When you wonder “cold peel vs hot peel” in using DTF transfers, differentiating the two helps you choose the best method for your projects. After learning their pros and cons, now you gain clear insights into when to use each type and what to expect from the finish. We hope that we have helped you in improving your transferring quality and save time in production.

On our website, we offer cold peel DTF transfers, ensuring your finish has the most durable adhesion. This type works great for any designs, especially the intricate ones. If you are about to start your DTF transfer projects, consider our product page here to access reliable, high-quality custom iron-on transfers.