Blog

What is a UV DTF Sticker? Your Complete Guide to This Innovative Sticker Type

In the world of printing, there’s a groundbreaking innovation that is taking stickers and labels to new heights: UV DTF stickers. These remarkable stickers have revolutionized the printing industry with their unique production process and exceptional print quality.

If you’re curious about what exactly UV DTF stickers are and how they can elevate your sticker game, you’ve come to the right place. This comprehensive guide will take a deep dive into UV DTF stickers, exploring their structure, production and benefits. Let’s join us to explore!

What is a UV DTF Sticker?

A UV DTF sticker is a type of sticker that uses a UV printing technique, which enables the direct application of ink onto a transparent and thin film material. This printing method allows for vibrant colors and intricate designs to be transferred onto the desired surface.

This type of sticker is known for its durability and unique appearance compared to traditional ones. Its slightly raised ink texture gives them a three-dimensional effect that makes them look like they are printed directly onto the object rather than being stuck on, allowing for a high-quality and professional look.

Principle of UV DTF Sticker creation

The principle of UV DTF sticker creation involves the utilization of UV digital print onto a transparent, thin film material.

This innovative and versatile UV sticker printing method follows a typical process:

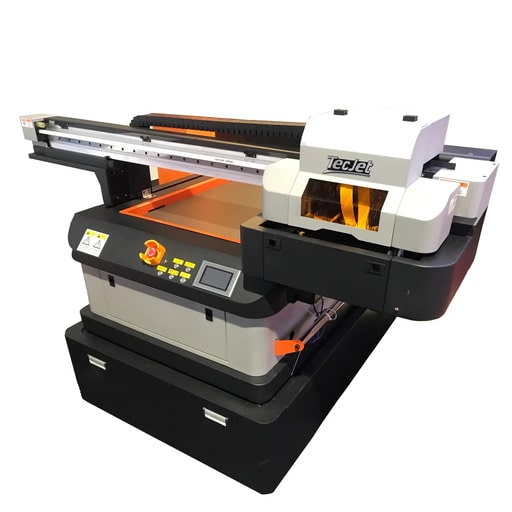

- Firstly, the design or image intended for the sticker is printed directly, and face down, onto a transparent film using a specialized UV DTF sticker printer. These printers are equipped with UV-curable ink, which is often preferred for its quick drying and curing properties.

- After the printing stage, the UV-curable ink undergoes a curing process. This is achieved by exposing the ink to ultraviolet (UV) light, which ensures that the ink dries and adheres to the underlying film. UV curing is crucial as it helps to enhance the ink’s durability and resistance to fading. In other words, we can answer yes to the question: “Is UV DTF waterproof?”, or “Is UV DTF stickers resistant to wear and tear?”

- Next, an adhesive is applied to the back of the printed image. The adhesive material can be either pressure sensitive or heat-sensitive adhesive. This layer enables the sticker to adhere to the desired surface when being applied.

- Then, a backing layer is added to hold the design in place and to provide protection for the adhesive until the sticker is used.

- Finally, the result is a UV sticker with 3 layers (the transfer film, the adhesive sticker and the backing layer) ready for use.

You may associate UV DTF stickers with traditional transfer stickers because of its 3-layer structure. However, these 2 types of stickers still have differences. Hence, in the next part, we will discuss how UV transfer stickers differ from regular vinyl transfer stickers.

How is UV DTF Sticker different from regular vinyl transfer stickers?

It is common to confuse UV DTF stickers with the regular transfer ones.

In both cases, they appear similar in structure as they both consist of 3 layers: the backing layer, the sticker layer and the transfer tape (or the film). Moreover, when being applied, the sticker layer in both cases is transferred onto the desired surface thanks to the transfer tape.

However, the two are fundamentally different.

Regular transfer stickers typically have a vinyl material as the sticker layer. This vinyl layer is printed on adhesive vinyl using different methods, such as screen printing or digital printing; or is cut from a solid-colored vinyl. Then, a transfer or application tape will be used to apply over the cut vinyl design. This tape keeps the design’s elements together until you’re ready to apply them.

On the other hand, UV DTF stickers have a unique printing process called UV printing. In this method, UV-cured ink is used to directly print onto the clear film, thus, the sticker layer is made up of this special ink, providing vibrant colors and excellent durability for the sticker.

Overall, the main difference lies in the printing process and the material used for the sticker layer. Regular transfer stickers can be printed using various methods and have a vinyl layer, while UV stickers specifically use UV-cured ink for the sticker layer, resulting in high-quality prints.

Our UV transfer stickers are UV DTF Stickers

Unlike regular transfer stickers from other sticker printing companies, our transfer stickers are created using UV print technology, so they are basically UV DTF stickers.

The outstanding advantage of our UV transfer stickers compared to vinyl transfer stickers is the use of UV-curable ink. This results in:

- Vibrant colors and crisp results regardless of how intricate the details may be.

- A slightly raised appearance, helps the stickers look like to be printed directly on the applied items.

- Also, the UV curing process ensures that our stickers are resistant to tearing, fading and can withstand various environmental conditions.

Where to buy UV DTF Stickers

To buy DTF stickers with vivid color and detailed designs, we recommend you purchase them from our website. We take pride in offering high-quality UV stickers that meet your expectations while keeping affordability in mind.

Our vibrant and high-quality UV stickers are perfect for creating eye-catching logos and adding professional-looking product labels. Additionally, thanks to excellent adhesion and durability, UV DTF stickers can be applied to a wide range of materials, including glass, plastic, metal, fabrics, leather, wood, and more.

So, for convenient and reliable UV DTF sticker purchases, go nowhere than CustomAny, where you can explore our product options and place your order easily.

6 expert tips to Prepare Artwork for printing UV DTF stickers

Because UV printing is an innovative process to produce complicated prints, preparing artwork for UV transfer sticker printing requires attention to details. After processing thousands of orders every month, we’ve compiled the following recommendations:

1. Avoid Overlapping Layers

Heavy ink coverage and overlapping colors can impact the clarity of your design. Simplify your artwork and minimize overlapping layers to maintain sharpness and definition.

2. Masking Layers

For multi-layer designs, use masking layers to separate colors and prevent unintended blending. For the best results, consult our printing experts to ensure the correct setup and alignment.

3. Color Density

The inks used in DTF can be highly saturated or vibrant. However, excessively dense colors may not dry properly and can result in ink smudging. So, if you are confused with your design colors, you can contact us to determine the optimal color settings for your design.

4. Use High-Resolution Images

To achieve sharp and crisp prints, provide us with high-resolution images. If images are printed at low resolution, they can be blurry or pixelated.

5. Create Safe Area

If you want to ensure that no crucial details (like text or images) are lopped off when your design is printed cut to the shape, maintain them in a safe region in your file.

6. Proofing and communication

Before printing, we will send you a soft proof via email for review. Take advantage of this opportunity to make any necessary adjustments or changes. Furthermore, don’t hesitate to communicate with your printing service if you have any questions or concerns during or after printing. We are there to assist and provide the necessary support.

Last thoughts

Through this guide on UV DTF stickers, we hope you have gained a complete understanding of this innovative printing technique to make informed decisions for your printing projects. Whether you are a business owner looking for vibrant and long-lasting stickers or an individual seeking to elevate your creations, UV DTF stickers offer a world of possibilities.

Now, it’s time to embrace the extraordinary with stunning, durable, and vibrant stickers that truly stand out!