Blog

What is DTF Powder: Its Benefits, Drawbacks, and Best Applications

What is DTF powder, and why does it matter in custom DTF printing – this is where to start our topic.

If you’ve worked with Direct to Film (DTF) transfers, you’ve probably seen the fine white layer in the back of the print. This layer is actually cured DTF powder, an essential ingredient that helps the printed design adhere to your fabric.

Whether you’re using finished custom DTF to customize your items, or learning to produce DTF transfers on your own, knowing “what is DTF powder” will help. So, keep reading to break down what DTF powder is, how it works and where it’s commonly used.

Learn about DTF Powder

DTF powder is an important element in the DTF transfers production; and “what is DTF powder” is a common question of those who might just enter this field.

1. What Is DTF Powder?

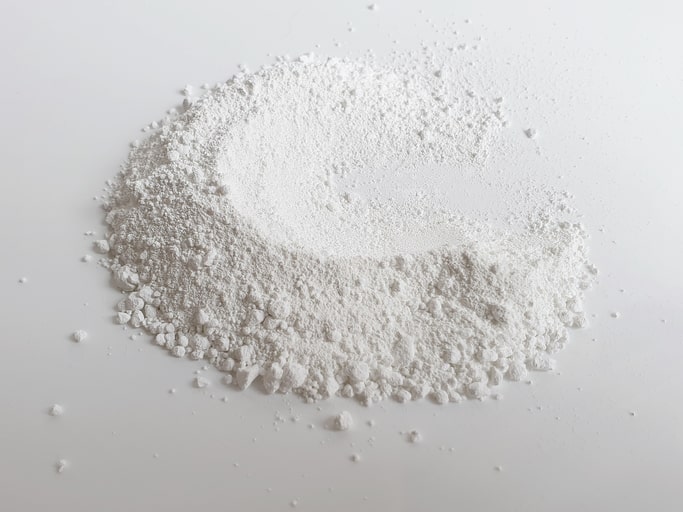

Firstly, let’s see “what is DTF powder”. In simple terms, DTF powder is a heat-activated adhesive powder used in DTF (Direct to Film) printing.

Specifically, this powder is cured to melt and left to cool down until it forms an adhesive layer in the back of the printed ink layer. This step results in a completed DTF transfer. Later in use, when this DTF transfer piece is pressed under heat and pressure, the adhesive layer made of DTF powder melts and bonds the design to the fabric surface.

Since the heat-activated adhesive layer acts as the bonding element between the printed design and the fabric surface, DTF powder, which this layer is made from, is indispensable.

This DTF powder works on different types of fabrics, both natural and synthetic. Thus, DTF transfers with DTF powder are used in various applications include:

- Custom t-shirts and hoodies

- Sports uniforms and jerseys

- Tote bags and hats

- Pillow covers and aprons

In short, DTF powder might seem like a small step in the process, but it’s what makes the entire DTF transfer durable and reliable.

2. Types of DTF Powder

The question “what is DTF Powder” also includes the acknowledgement of its different types. In fact, DTF powders come in several varieties based on their color, finish, and grain size.

By color, we have two types:

- White powder: This is the most common type, as they are suitable for light and most colored fabrics.

- Black powder: This type of powder is used to create DTF transfers designed for dark fabrics. This way, you can prevent unwanted white halo lines from appearing around designs after heat pressing the DTF transfers on fabric.

Besides being classified by color, we can divide them into matte and glossy powder; or into fine, medium and coarse powder if we consider them by grain size.

In short, each type of DTF powder has its unique use, and selecting the suitable one for your project decides how good your print looks and how long it lasts.

How does DTF Powder work?

After knowing “what is DTF Powder”, let’s walk through the process and see how DTF powder does its job in DTF transfer production.

How DTF Powder is used in the Printing Process:

Firstly, a design is printed onto a clear film using DTF ink

Next, adhesive powder will be evenly sprinkled over the back of the ink layer which is still wet. This powder sticks only to the printed areas.

Then, the film, now coated with powder, is heated in a curing oven or with a heat gun. This step melts the powder slightly, forming a soft, heat-activated adhesive layer behind the design.

Once cured, the film is ready for transfer.

How DTF Powder works during the transfer process:

When it comes to transferring the finished DTF transfer, DTF powder serves to bond the printed design layer to the fabric. Here how it works:

- The DTF transfer is placed onto the fabric with the printed design facing up and the cured powder side directly touching the garment.

- Heat and pressure is applied using a heat press or a household iron. The heat will make the adhesive layer (which is made from DTF powder) melts down.

- As the powder melts, it binds the ink design to the fibers of the fabric, making the print adhere to the surface.

- Lastly, the film layer is peeled away, leaving only the printed ink design cleanly transferred onto the fabric.

This simple but clever process is what makes DTF printing so versatile. The heat activated DTF powder layer allows DTF transfers to adhere to anything, from T-shirts to tote bags, from jackets to pants,…

Pros & Cons of DTF Powder

When you are wondering “what is DTF powder” or “why do so many people use DTF transfers”, you can find the answers by discovering this powder’s pros.

Pros of DTF Powder

DTF powder is popular thanks to the benefits it brings to DTF transfers production:

- Easy to use: With the help of DTF powder, which can melt down and get sturdy back again, you no longer need to print directly onto the fabric.

- Excellent adhesion: DTF powder provides strong adhesion when it is used on various different fabrics like cotton, polyester, blends, or even nylon.

- Good stretch and durability: When applied properly with quality materials, the DTF adhesive layer allows your DTF prints to stay on the fabric for a long time without cracking and peeling.

The invention of DTF powder has made customizing fabric products much easier and more flexible.

Cons of DTF Powder

Despite its several pros, there are a few things to watch out for when using DTF powder:

- Requires precise application: This powder needs to be applied evenly, and both curing temperature and timing must be controlled carefully. Too much or too little powder, or curing too long or too short, can affect the look and durability of the final result.

- Storage issues: If not stored properly in a dry, cool place, DTF powder becomes wet and clump together. This lowers its adhesive quality and makes it harder to apply evenly on the printed ink.

Knowing these pros and cons of DTF powder, one of the most important elements to produce DTF transfers, you can get better, more reliable results with DTF printing.

Real-World Applications of DTF Powder

What is DTF powder used for in real-world projects? DTF transfers that are made using the DTF powder are not just for t-shirts. Because of its flexibility and strong adhesion, this heat-activated adhesive helps transfer printed designs to various items across many industries, such as:

- Fashion and apparel: DTF transfers are used for personalizing clothing items, from t-shirts, hoodies, jackets, to hats and caps. The DTF powder works well on both light and dark fabrics.

- Home decor: People take advantage of DTF powder to add designs to pillows, blankets, table runners, and even fabric wall art.

- Merchandise and gifts: Custom POD shirts, tote bags, and accessories we see everyday often feature designs transferred with DTF powder. Transferring is a simple solution for small businesses or those who love gift-making.

- Promotional items: DTF transfers with the use of DTF powder are great for branding items like banners, caps, and uniforms at events or for company giveaways.

Last thoughts

What is DTF Powder and how it works are now clearer than ever. With all the knowledge about DTF powder as well as its application in DTF transfer production we have gained from this article, you can choose the right materials and techniques for your printing projects, whether for apparel, home decor, or promotional items.

If you want to explore more, you can check out our other blog posts about DTF powder, DTF transfers or learn creative ways to use custom prints.