Blog

What Material Can DTF Be Used On? 9 Best & Worst Surfaces Ranked

If you’re new to using DTF transfers or just starting to learn more about them, one of the most common questions is: What material can DTF be used on? With so many fabrics and surfaces, you need to know which work best and which don’t. Knowing what material can DTF be used on will also help your transfers last and look great.

Therefore, in this guide, we’ll rank the 9 best and worst surfaces for DTF transfers. If you’ve ever wondered what material can DTF be used on or what can you put DTF transfers on, this ranking will help you decide what to use for your next project!

Get to know DTF Transfers

When talking about DTF transfers, we mean custom iron-on DTF transfers, a common product that is used to transfer designs onto garments.

DTF (Direct-to-Film) transfers are printed designs on a special film, made using a specific process. The design is first printed onto the film, coated with adhesive powder, and then cured. Once ready, it can be applied to fabric using heat and pressure. The result is a bright, durable print.

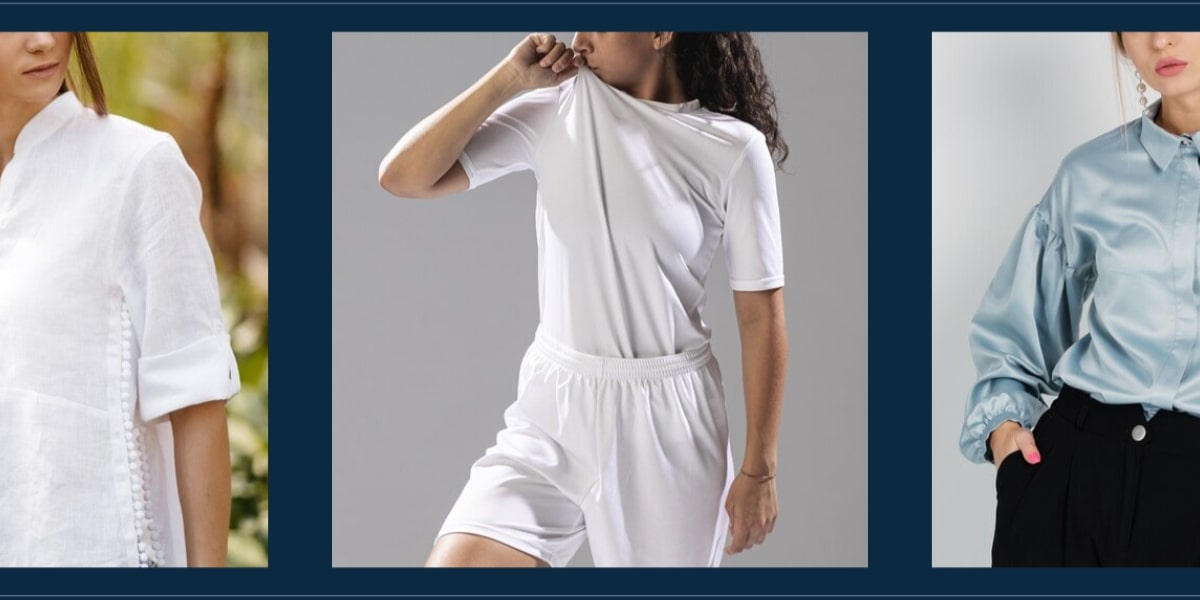

These are perfect for creating personalized t-shirts, bags, hats, and more. Using iron-on DTF transfers lets you achieve high-quality printed products without having to deal with complicated setups.

For more information, you can check out our blog: “Custom Iron-On Transfers: What They Are & How to Use Them“.

What Makes a Material Good for DTF Transfers?

When exploring the question “what material can DTF be used on”, it’s essential to understand which materials work best for DTF transfers. Understanding these factors helps you pick the best surfaces and avoid costly mistakes.

1. Surface texture

A smooth surface always gives the best results with DTF transfers. It helps the design stick evenly and look sharp.

However, slightly textured materials can still work, especially if you want a more rugged or creative effect. The key is avoiding anything too rough, which can make your print look patchy or unclear.

2. Heat resistance

Since DTF transfers require heat to adhere to the fabric, the material must be able to withstand the temperature.

Some materials, like nylon, silk, or leather, are sensitive to heat and may melt or change color during pressing, which can ruin your design. That’s why it’s important to check the fabric’s heat resistance before applying iron-on DTF transfers.

3. Fabric weave & stretch

The fabric’s weave and stretchiness are also essential factors. Transfers adhere better to tight weaves. On the other hand, stretchy fabrics can make the design crack over time, especially after washing.

So, for best durability, you should choose stable materials with little stretch.

4. Moisture absorption capacity

Materials that absorb a lot of moisture, like untreated cotton, can make it harder for the adhesive to stick well. On the contrary, materials that resist water too much might prevent the glue from sticking.

Hence, you should choose a material that provides both absorption and adhesion to get the best result.

5. Fabric Weight and Thickness

The weight and thickness of the fabric gently affect how heat spreads during the transfer process.

Lighter, thinner materials can sometimes move or wrinkle under the heat press. Conversely, thicker fabrics, like hoodies or tote bags, usually stay in place better. Their added weight helps keep the fabric flat and firm under the heat press.

That’s why selecting a stable fabric is crucial to ensuring a clean and long-lasting result.

Ranked: Best & Worst Materials for DTF Transfers

Now that you understand what makes a material good for DTF transfers, it’s time to look at specific examples to answer the question “what material can DTF be used on?” Let’s find out the best and worst surfaces for DTF, based on performance, durability, and final appearance.

1. 100% Cotton — Excellent

When it comes to DTF transfer on cotton, this natural fiber is a top choice. It holds color beautifully and handles heat well.

So, for the wonder, “can DTF print on cotton?” The answer is: Absolutely, and it lasts with proper care.

2. Cotton/Polyester Blends — Excellent

Blends offer the best combination of cotton’s softness and polyester’s strength. These are among the best materials for DTF because they resist shrinkage and provide excellent print clarity.

3. Polyester — Good

When thinking about “what material can DTF be used on”, have you ever asked if DTF works on polyester? Yes, it does. While the color vibrancy may vary slightly, the result is still strong. It’s also a popular choice when wondering “what can DTF be applied to”.

4. Denim — Good

Denim’s tight weave makes it a reliable option. It may require firm pressing, but transfers adhere well to jean materials.. It’s ideal when thinking about “what can you put DTF transfers on” besides T-shirts.

5. Fleece — Good

Fleece’s soft, slightly fuzzy surface works well with DTF transfers, especially when pressed at moderate heat.

6. Tri-blend (cotton/poly/rayon) — Good

A popular choice for trendy apparel, tri-blends are both comfortable and stretchy. While slightly more delicate, they hold prints well if pressed correctly.

7. Linen — Moderate

Linen can wrinkle and stretch under heat, so results may vary. Use with care if you are concerned about the DTF printing durability.

8. Silk/Satin — Moderate

Silk and satin, both delicate and heat-sensitive, require low-temperature pressing to prevent scorching. They are not ideal for high-stretch items, but workable for special projects.

9. Spandex/Elastane Blends — Moderate

Spandex or elastane blends are known for their high stretch and flexibility. While DTF transfers can be applied to these fabrics, the constant stretching may cause the design to crack over time.

If you choose to use DTF on this material, it’s best to opt for smaller designs and avoid placing prints on high-stretch areas.

Final Tips Before You Press

After reviewing the materials best suited for DTF transfers, it’s time to focus on achieving the best results. No matter “what material can DTF be used on”, proper application technique is as crucial as fabric choice.

Adjust heat & pressure for fabric type

The heat and pressure reaction of DTF transfers varies by material. For example, thick cotton needs more pressure, while delicate fabrics like satin require lower temperatures.

Therefore, adjusting your settings based on the fabric ensures that the transfer bonds well without damaging the surface. This step is especially important when working with the best fabric for heat transfer, as even high-quality materials can be ruined by excess heat.

Always test a swatch

Before applying your design to the final product, always test a small piece of the material. This helps you see how the fabric responds to the press. Whether you’re wondering what material can DTF be used on or trying something new, a quick test can prevent costly mistakes.

Last words

Hopefully, you now have a clear understanding of “what material can DTF be used on” and how each surface affects the final result. Choosing the right material isn’t just about appearance, it plays a big role in how well the transfer adheres and how long it lasts.

If you’re looking for a reliable way to apply your designs with DTF transfers, our website offers custom iron on transfers that work beautifully on many of the best-rated fabrics. Let’s visit and choose the perfect ones for your project!