7 Sticker & Label printing technologies for A Better Look

Stickers and labels are a crucial element of branding and marketing. They help to identify products, provide important information, and create a lasting impression on customers. To make your stickers and labels stand out, it’s advisable to try different printing methods, especially the advanced ones. In this article, we’ll explore top 7 sticker and label printing technologies that bring out a high-end appearance that makes your designs look much more professional.

1. Custom die cutting

Custom die cutting is the first sticker and label printing technology to mention. It is a printing technique that involves using a specialized cutting tool, or die, to cut a sticker or label into a specific shape or design. Unlike traditional printing methods that produce square or rectangular shapes, custom die cutting allows for a wide range of shapes, sizes, and designs to be created.

Custom die cutting allows stickers and labels to be cut into unique shapes and designs, such as the shape of a logo or product image, creating a more visually interesting and eye-catching design. The unique and memorable shape enhances brand recognition, making the sticker or label stand out from competitors.

Custom die cutting can be used on a wide range of materials, including paper, vinyl, and plastic, making it a versatile technique for creating high-quality stickers and labels.

There are some specific types of designs that work well with custom die cutting:

- Logos and brand names: Custom die cutting can be used to create stickers and labels in the shape of a logo or brand name, creating a unique and memorable design that enhances brand recognition.

- Product images: Custom die cutting can be used to cut stickers and labels into the shape of a specific product image, such as a bottle or package, making the design more visually interesting and appealing to customers.

- Geometric shapes: Custom die cutting can be used to create stickers and labels in unique geometric shapes, such as circles, squares, or hexagons, adding a modern and unique touch to the design.

- Personalized designs: Custom die cutting can be used to create personalized stickers and labels for specific events or occasions, such as weddings or birthdays, creating a unique and memorable keepsake for guests.

2. Metallic inks – one of the special label printing technologies

Being a special type of printing ink that contains metallic particles, the second label printing technology – using metallic inks, gives your designs a lustrous, shimmering effect. This label printing technology can be used to create stickers and labels that are attention-grabbing and eye-catching.

Metallic inks can help your stickers and labels stand out from the competition, as they catch the light and create a striking effect. You can mix metallic inks with other inks to create custom colors and effects, allowing for a unique design. This ink can be used on a wide variety of materials, including paper, plastic, and even metal. Additionally, metallic inks are typically more resistant to fading and smudging than other types of inks, making using this sticker and label printing technology a good choice for long-lasting products.

Designs that go well with metallic inks include:

- Geometric shapes: Metallic inks can be used to create sharp, angular shapes, which can look particularly striking when combined with contrasting colors.

- Logos and typography: Metallic inks can add a touch of elegance to logos and typography, making them stand out and creating a sense of sophistication.

- Abstract patterns: The shimmering effect of metallic inks can be used to create abstract patterns that catch the eye and add visual interest to your stickers and labels.

- Illustrations and images: Metallic inks can be used to highlight specific elements of an illustration or image, creating a dynamic and eye-catching effect.

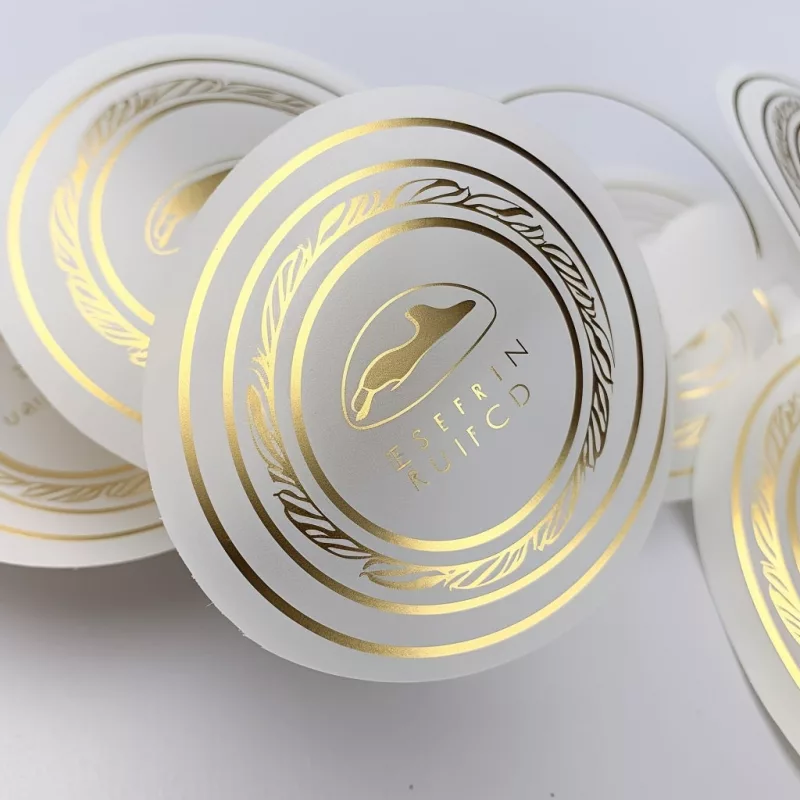

3. Foil stamping

Foil stamping is a label printing technique that uses a heated metal die to press and adhere a thin layer of foil to the surface of a material, such as paper or plastic. Foil stamping can create a metallic or matte finish on stickers and labels, adding a touch of elegance and sophistication to the design.

Foil stamping can create a three-dimensional effect on the sticker or label, making the design more tactile and interesting to touch and look at. The contrast between the foil and the background material can make the design stand out and more noticeable on store shelves. This sticker and label printing technology also add a touch of luxury and sophistication to the design, so that it appears more high-end and exclusive.

You should utilize foil stamping technique for:

- Logos: Foil stamping can be used to highlight certain elements of a logo, such as the company name or emblem, making it stand out and adding a touch of elegance.

- Geometric shapes: Foil stamping can create a striking contrast between the foil and the background material, making it ideal for designs featuring bold, geometric shapes.

- Floral designs: Foil stamping can be used to add a delicate, metallic finish to floral designs, adding a touch of elegance and sophistication.

- Monograms: Foil stamping can be used to add a touch of personalization to stickers and labels, making them ideal for monogrammed products such as wedding favors or gift items.

4. Holographic foils – a printing technique for young and trendy designs

Holographic foils are a type of decorative material that can be used to create a dynamic and eye-catching effect on stickers and labels. They feature a special holographic pattern that reflects light in different ways, creating a futuristic and attention-grabbing effect.

Holographic foils are a relatively uncommon design feature, making them stand out from other stickers and labels on the market. The holographic pattern on the foil can create a futuristic and modern look, making it ideal for products targeting a young and trendy demographic. Their unique reflective pattern can catch the eye and draw attention to the product.

Like other types of foils, holographic foils are durable and long-lasting, providing an extra layer of protection to the sticker or label.

This printing technology can be used in a variety of different ways, from subtle accents to full-coverage designs. They can also be used in combination with other design elements, such as metallic inks or foil stamping, to create a multi-dimensional effect.

Here are the uses we suggest for holographic foils:

- Abstract patterns: Holographic foils can be used to create intricate and abstract designs, making them ideal for products targeting a creative and artistic audience.

- Geometric shapes: The reflective properties of holographic foils can enhance the sharp lines and angles of geometric designs, making them appear more futuristic and high-tech.

- Product logos: Holographic foils can be used to highlight certain elements of a product logo, making it stand out and appear more dynamic.

- Celestial designs: The reflective properties of holographic foils can also be used to create designs inspired by the stars and galaxies, making them ideal for products in the beauty or fashion industries.

5. Letterpress printing

Letterpress printing is one of different types of printing presses. In this label printing technology, a metal plate is used with a raised design to create an impression on paper or other materials. This creates a distinctive, tactile effect that can add a vintage or handcrafted look to stickers and labels.

This label printing technique produces high-quality, precise prints with rich colors and deep impressions. Letterpress printing plates can be customized to create a wide range of designs, including intricate patterns and detailed illustrations. The special point of letterpress printing is it uses minimal ink and does not require the use of harsh chemicals, making it a more eco-friendly option.

There are some types of designs that work well with letterpress printing:

- Vintage-inspired designs: The tactile effect created by letterpress printing can add an authentic vintage look to designs inspired by antique typography, botanical illustrations, or retro patterns.

- Minimalist designs: The simplicity and elegance of minimalist designs can be enhanced by the subtle texture and depth created by letterpress printing.

- Organic and natural designs: Letterpress label printing technique can enhance the natural and organic look of designs inspired by botanical illustrations, hand-drawn sketches, or textured patterns.

- Premium products: The high-quality, tactile effect of letterpress printing can add a premium and luxurious feel to stickers and labels for high-end products like wine bottles, cosmetics, or artisanal food products.

6. Embossing and debossing

Embossing and debossing are sticker and label printing techniques that create a three-dimensional effect on stickers and labels. Embossing raises the design on the surface of the material, while debossing presses the design down into the material, creating an indentation.

Both techniques add depth and texture to the design, making it stand out and enhancing its visual impact. This gives a premium feel to stickers and labels, creating a sense of luxury and quality. The embossed or debossed design is more durable than a flat design, as it is less prone to fading or scratching.

Embossing and debossing can be great for:

- Logos and brand names: Embossing or debossing the logo or brand name on the sticker or label can make it more memorable and reinforce brand recognition.

- Geometric patterns: Embossing or debossing geometric patterns, such as stripes or circles, can create a visually appealing texture that adds interest to the design.

- Organic shapes: Embossing or debossing organic shapes, such as leaves or flowers, can create a natural and tactile effect that enhances the design’s theme.

- Textured backgrounds: Embossing or debossing a textured background, such as wood grain or marble, can add depth and interest to the design, making it more visually appealing.

7. Spot UV coating

Spot UV coating is the last printing technique we discuss. It involves applying a high-gloss varnish to specific areas of a sticker or label, creating contrast and visual interest. The varnish is applied to a specific area using a separate printing plate, which allows for precise placement of the coating.

Spot UV coating creates contrast by making certain areas of the sticker or label more glossy and reflective than others. This high-gloss label finishing creates a visually interesting effect that draws the viewer’s attention and adds depth to the design.

This label printing technology adds a layer of protection to the printing product, making it more durable and resistant to wear and tear. Spot UV coating can be used on a wide range of materials, including paper, vinyl, and plastic.

Uses of spot UV coating in making stickers and labels:

- Logos and brand names: Applying spot UV coating to the logo or brand name can create a high-end, professional look that enhances brand recognition.

- Geometric shapes: Spot UV coating can be used to highlight specific geometric shapes, such as squares or circles, creating a contrast between the glossy and matte areas.

- Product images: This label printing technique can be used to highlight specific areas of a product image, such as the product name or key features, drawing attention to the most important aspects of the design.

- Patterns and textures: Spot UV coating can be used to create interesting patterns or textures, such as a raised pattern on a wallpaper design or a glossy texture on a metallic design.

Conclusion

In today’s competitive marketplace, it’s more important than ever to make your products and branding stand out. By using one or more of the printing technologies discussed in this article, you can create the best label and best sticker printing that are not only high-quality but also catch the eye and leave a lasting impression on your customers.

Whether you’re looking to create a vintage look with letterpress printing, add texture with embossing and debossing, or create contrast with spot UV coating, there’s a printing technology that can help you achieve your goals. So don’t settle for ordinary stickers and labels – explore the possibilities of these sticker and label printing technologies and give your products the attention they deserve.