Blog

Custom Stickers 101: The Complete Guide

Custom stickers have become a versatile tool for both personal creativity and professional communication. People use them to decorate belongings, organize spaces, promote brands, and share messages in a simple yet effective way through customizable designs.

With so many materials, printing methods, shapes, and finishes available, choosing the right option can feel overwhelming at first.

Thus, our guide will show you all you need to know about custom stickers in a clear and practical way. Explore to create stickers that perfectly match your preference and purpose!

1. What are Custom Stickers

1.1. What Are Stickers?

Before exploring custom stickers, it is important to first understand what stickers are. Stickers are printed graphics designed to adhere to various surfaces permanently or temporarily. These versatile items get created through specialized printing processes on different substrate materials. Every sticker has a basic structure:

- Face stock forms the visible surface where designs appear

- The adhesive layer provides the sticking power.

- A backing layer protects the adhesive for application.

Besides, many custom stickers include additional laminate coatings for durability. Some specialty types feature unique construction with transfer tape or film, which is useful for many purposes.

Read more: “What is sticker lamination?“

1.2. Custom Stickers

So, what transforms a simple sticker into a custom one? The word “custom” implies that you can make any design you want. These stickers are made specifically for individual needs.

Unlike mass-produced options, these custom made stickers allow you to freely decide the artwork, shape, size, material, etc. When you buy custom stickers or print custom stickers online, you’re getting something truly unique.

1.3. Custom Stickers Uses

Regular stickers typically serve decorative and some more other purposes. Custom stickers, on the other hand, offer much broader applications for both individuals and businesses because they are customized to match specific needs.

For personal uses, you can create custom vinyl stickers, custom bumper stickers, custom car stickers, custom waterproof stickers,… for decorating, crafting, etc.

For business applications, stickers custom allows you to make many custom business stickers like:

- Custom logo stickers

- Custom packaging stickers

- Custom product labels

These custom stickers for business are perfect for guiding or to strengthen branding, marketing, and promoting.

2. Custom Sticker Materials

Material refers specifically to the sticker’s face stock—the top layer. It is the final part that remains after you peel off the backing and apply your sticker. Therefore, choosing the right material is the secret to creating amazing sticker results.

2.1. Paper

If you want to order custom stickers on a tight budget, paper is among cheap custom stickers options. You can find them in white or kraft options.

For eye-catching, colorful designs, white paper is ideal, whereas kraft paper offers a handcrafted, rustic look.

However, this material is not resistant to water, so it works perfectly for indoor applications.

2.2. Vinyl

If you’re looking for a durable option, vinyl is your go-to material for custom sticker printing.

These mid-range price stickers offer strength and flexibility for custom-made stickers that need durability. This flexible plastic can withstand water, sunlight, and scratches.

Additionally, vinyl comes in various types, including:

- White vinyl supports vibrant colors

- Clear vinyl blends into surfaces

- Holographic or metallic vinyl creates eye-catching reflex effects

2.3. BOPP (Polypropylene Film)

BOPP is a high-end plastic film that is thin yet tough. It is similar to vinyl but is often used for labeling.

This material is waterproof and resistant to oils and many chemicals. It is a type of polypropylene that is also available in white, clear, holographic, and metallic styles.

Many businesses print custom stickers using BOPP for a professional finish and excellent durability.

2.4. Special Material

In addition to the basics, there are specialized materials that offer unique textures and application methods.

- UV-curable Ink: This ink creates UV DTF transfer stickers without any face stock layer needed. It results in highly durable designs that transfer onto hard surfaces without a background.

- PVC Foam: This material is used to create puffy stickers with a raised 3D effect.

- Static Cling: This special material adheres to surfaces using static electricity instead of adhesive, making it removable and reusable.

Related blog: “Static Clings 101: How do non sticky stickers work?“

These specialty options are typically more expensive due to their complex production. They are perfect for professional applications, promotional campaigns, or decorative items that cannot be achieved with standard materials.

2.5. Eco-friendly Materials

For something sustainable, eco-friendly materials are an excellent option. If you are researching how to make custom stickers with less environmental impact, this is the answer.

These materials are made from sustainable sources, like recycled paper and sugarcane fiber. Their durability is similar to standard paper, making them best suited for indoor applications. They are slightly higher than standard paper but an affordable choice for conscious branding.

Eco-friendly materials are great for brands with an environmental focus, organic product labels, and businesses wanting to showcase their commitment to sustainability.

3. Custom Sticker Printing Methods

After exploring different materials, let’s take a look at how printing methods shape the final look and feel of your stickers!

3.1. Digital Printing (Most common)

This method is the most common choice for smaller orders. It perfectly handles complex designs with impressive speed. Digital printers produce vibrant colors on materials like paper, vinyl, and BOPP. You can select between inkjet for rich color depth or laser printing for exceptionally sharp precision.

You may want to read: “What is Digital Printing: How It Works, Best Applications & Final Product“

3.2. Offset Printing

When you need a massive quantity of stickers, offset printing becomes your most economical option. This technique produces exceptionally sharp and consistent quality for the entire printed sticker.

Read more: “Offset Printing vs Digital Printing“

3.3. Flexographic Printing

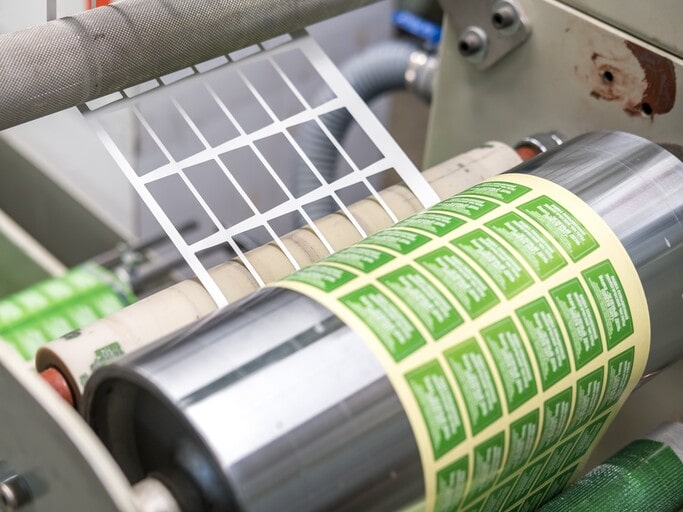

Flexography excels at printing huge quantities of stickers on rolls. This high-speed process is often used in commercial labeling, ensuring efficiency and consistency for mass-market items that require fast and reliable production.

3.4. UV Printing / UV-Curable Ink Printing

UV printing uses special inks that dry instantly when exposed to ultraviolet light. This process creates vibrant colors, waterproof and scratch-resistant stickers. Its incredibly durable outcome makes it a fantastic choice for those who want premium stickers.

3.5. Screen Printing (Silkscreen)

For stickers with bold, solid colors, screen printing offers excellent quality. It applies a thick layer of ink, resulting in exceptional vibrancy and extreme durability. These characteristics make screen-printed stickers the best choice for outdoor applications.

Read more: “Screen Printing vs Digital Printing“

3.6. Thermal Printing

Thermal printers work best for functional labels. They rapidly produce barcodes, shipping labels, and other stickers with variable data. Their high speed is especially valuable in warehouses or logistics centers.

3.7. Letterpress / Embossing / Foil Stamping

To give your stickers a luxurious and memorable touch, consider special finishing methods. Letterpress, embossing, and foil stamping create stunning effects. These techniques add texture, raised elements, or a brilliant metallic shine, elevating your brand and appealing to a high-end market.

4. Custom Sticker Types

Here are some of the custom sticker types you can choose from, so you can decide what works best for you.

4.1. Based on Customization Level: Partially vs. Fully Custom

When you start creating custom stickers, there are 2 customization options to choose from:

- Partially custom stickers: These stickers allow you to add text or a simple graphic to a pre-designed template. This is a quick and often affordable option.

- Fully custom stickers: This option gives you complete creative options. You provide the full design, making the sticker uniquely yours.

4.2. Based on shape: die cut and uniform shape

The sticker’s shape can significantly enhance its look and usability.

- Uniform shapes (like circle stickers or square stickers) provide a classic, clean look that is ideal for professional branding on products and packaging.

- Die-cut stickers are custom-shaped to match your design’s exact outline. You should consider a die-cut shape for a logo, a character, a unique symbol,…

4.3. Based on cutting method: die-cut and-kiss cut

This refers to how the stickers are cut on their backing sheet.

- A kiss-cut slices through the sticker layer but leaves the backing paper intact. This makes the stickers easy to peel off individually while keeping the sheet together.

- A die-cut cuts through both the sticker and the backing, creating individual pieces.

Kiss-cut is perfect for sticker collections or multi-design sheets, while die-cut sheets are ideal for separated, ready-to-apply stickers.

For more information, you may want to read: “Kiss cut vs die cut stickers“

4.4. Based on format: singular, sticker sheet, sticker roll

Finally, consider the delivery format.

- Singular stickers come as individual, pre-cut pieces, perfect for direct use or handouts.

- Sticker sheets group multiple designs or copies on a single backing sheet, great for packaging and retail.

- Sticker rolls come on a long continuous roll, which is the most efficient format for high-volume applications like shipping labels, event giveaways, or warehouse use.

5. Where to Use Custom Stickers

Custom stickers have many practical and creative applications. Their applications are for:

Individuals

Decorating

Custom stickers offer a fantastic way for self-expression. You can decorate your:

- Laptop

- Phone cases

- Water bottle

- Journals or planners

- …

This helps express your style and make everyday items feel like your own.

Level up your crafts

For crafters or artists, stickers are a versatile tool. You can use them for:

- Highlighting special moments in scrapbook

- Adding detail to handmade cards

- Creating beautiful decals for DIY home decor

Custom stickers give your creations a polished, eye-catching look..

Organization and Labeling

Stickers help keep things organized in a stylish way. You can use them to label kitchen containers so ingredients are easy to find. Boxes in the garage or closet also become easier to recognize with custom labels. For office use, they help organize files and supplies efficiently.

Besides these applications, custom stickers can be used in many other practical ways. And a well-labeled space with custom stickers creates a more functional environment for work or home life.

Businesses

Product & Packaging labeling

This is one of the most common applications for businesses. A custom sticker can:

- Display your logo

- Lists ingredients or materials

- Provides usage instructions

- Includes barcodes for retail scanning

A high-quality, durable label on a jar, box, or bottle gives a more professional and reliable impression.

Branding

For any business, stickers are a simple and powerful branding tool. They help build a professional image when you place your custom logo on:

- Product packaging

- Thank you cards

- Envelopes

- Merchandise

Every sticker acts as a perfect brand identity for your company.

Marketing

Custom stickers are a cost-effective marketing tool. They travel easily and spread messages naturally when customers share them.

You can use stickers on:

- Event materials

- Product samples

- Storefronts

- Giveaway items

This is an excellent method that gives your brand repeated visibility.

Promote Events

Custom stickers make excellent promotional items for:

- Concerts

- Fundraisers

- Community events

- Social campaigns

They are easy to distribute, and when people display them, they become a great tool to spread your message.

Storage and Logistics

Many warehouses and offices use custom stickers to organize bins, shelves, and inventory. These stickers improve workflow, help track items and guide staff quickly.

6. How to Design Custom Stickers

Now, it’s time to design your own custom stickers with these simple steps!

6.1. Start With Your Sticker Goal

First, you need to define your sticker’s purpose. A sticker for a business requires a professional design, while a personal one offers creative freedom for decoration.

Then, think about the message you want to convey. Your design should clearly show this message.

You also need to decide on the feeling you want. A cute or aesthetic style appeals to a different audience than a bold, minimal, or retro design.

This initial step helps guide all next creative choices you will make.

6.2. Choose Your Starting Point

Custom sticker design offers a wide range of creative possibilities. Your inspiration can come from anywhere.

You can use an existing image, like a favorite photograph or a company logo. This option provides a quick and effective starting point.

Alternatively, you can create a brand-new artwork. Many people also combine elements, merging text, illustrations, and photos into a unique composition that perfectly expresses their styles.

6.3. Refine Your Design Details

Once you have a basic concept, you should refine the smaller detail like:

- Clean up and arrange your layout

- Remove any unnecessary clutter

- Add supporting design elements, like white or colored borders, subtle drop shadows,…

6.4. Common Sticker Design Mistakes

Avoiding common technical errors is crucial for a successful print. For the perfect final quality, you should notice and avoid these key mistakes:

- Spelling and grammar errors.

- Low resolution files (below 300 DPI), which cause blurriness.

- RGB/CMYK color mode issues, as printers use CMYK.

- Raster versus vector file confusion, affecting scalability.

- Inefficient or missing bleeds, which can leave white edges.

- Submitting the wrong file format for production.

- Failing to get a proof before final printing.

To learn more about these errors and how to correct them, you can read more in our detailed guide “7 Terrible Mistakes to Avoid when Getting Your Sticker File Ready for Printing”.

7. How to Choose the Right Sticker Types

Choosing the right sticker type saves time and avoids disappointment. A few clear checks help designs perform better when you use them.

7.1. Match the Design With the Sticker Type

Your artwork’s details greatly influence your ideal sticker type. A design with a unique outline looks fantastic as a die-cut sticker. Clear stickers or UV DTF transfer stickers work best for simple logos or text that need to blend into a surface. The shape and complexity of your art will guide you to the best material and cut for the best result.

7.2. Consider the Purpose of Use

Consider where you will apply your sticker and what you will use them for. You might want a sticker to brand your products with a professional finish. Maybe you need a durable sticker for a car bumper. A fun design could personalize your laptop or water bottle.

Each application requires a different kind of sticker to achieve your goal effectively.

7.3. Evaluate External Factors

Next, you should consider the environment when choosing custom stickers. Constant sunlight exposure requires a UV-resistant laminate to prevent fading. Besides, stickers on drinkware must be waterproof to survive washing and weather. Or a sticker on a high-touch item like a phone benefits from a scratch-resistant coating for protection.

These features ensure your sticker remains durable and vibrant when being used.

8. How to Choose the Right Sticker Size

Selecting the right sticker size can significantly impact how your design is felt and used. Therefore, let’s consider:

8.1. Measure the Available Space

You should leave a small margin of white space around your sticker to provide a clear boundary for your design. A buffer of at least 0.25 to 0.5 inches creates a professional appearance. This space helps your design stand out more effectively against its background.

8.2. Think about Visibility

A sticker that is too small becomes difficult for people to see and appreciate. Conversely, an overly large sticker might overwhelm the object and look aesthetically unpleasing.

You should also consider your application style. For example, a single sticker might be larger for maximum effect. On the other hand, a collection for “sticker bombing” requires many smaller, varied sizes to fit together. This creates a dynamic and layered visual effect.

8.3. Standard sticker sizes

Many common applications have standard sticker dimensions that work best. Each size fits on different items like laptops, water bottles, and packaging.

Therefore, it’s best to find the perfect dimensions for your project. You can explore our article “Sticker size guide: Best sticker size for popular uses” for more specific recommendations.

9. How Long Do Custom Stickers Last?

The longevity of custom stickers varies depending on the type of sticker and how it is used, such as:

9.1. Outdoor vs indoor

The environment where a sticker is placed plays a big role in its longevity.

When used indoors, stickers are protected away from harsh weather, often lasting for several years.

Conversely, stickers applied in outdoor spaces are constantly exposed to rain, wind, and temperature changes. For this reason, durable materials like vinyl are essential for any sticker for the outdoors. This ensures they can endure for a few years, maintaining their appearance against tough conditions.

9.2. UV exposure

UV exposure is another factor that affects how long custom stickers last. Prolonged exposure to sunlight can cause colors to fade and materials to weaken over time. That’s why stickers placed outdoors or near windows are more likely to experience UV damage than those used indoors.

In this case, using UV-resistant inks or protective laminates can help reduce fading and extend the sticker’s lifespan.

9.3. Waterproofing

Moisture can quickly ruin a standard sticker by weakening its adhesive and causing the material to degrade. Because of this, stickers last much longer when made with waterproof materials. When paired with a waterproof adhesive, they can withstand water perfectly.

9.4. Heat resistance

High temperatures can be another damage. Extreme heat can cause the glue to soften and fail, leading the sticker to peel away. Moreover, direct heat can even warp or melt certain materials.

High temperatures can also affect how long a sticker lasts. Heat may reduce adhesive performance and impact certain materials over time.

For this reason, choosing a durable sticker is important. You should also share details about where the sticker will be applied and how it will be used to allow suppliers to recommend the most suitable option.

10. How Much Do Custom Stickers Cost?

Custom stickers are a remarkably cost-effective item, making them accessible for businesses and individuals alike. However, there are some factors that affect their cost:

- The material: durable vinyl, for instance, costs more than standard paper.

- Sticker’s size also directly impacts the price because larger designs require more resources.

- A protective lamination, such as for UV, scratch resistance, will increase the price

- The total quantity you order directly affects the per-item price.

Especially, ordering a larger quantity dramatically lowers your cost per sticker. Printers often offer significant discounts for bulk orders because they optimize their materials and press time. For instance, the cost for your hundred stickers is much lower than the cost for your ten.

Hence, if you need stickers for a long-term project, a marketing campaign, or regular business use, buying in larger quantities provides the best overall value. This approach ensures you get the best custom stickers for your budget.

11. How to Order Custom Stickers

You can find many online printers and local shops that produce custom stickers. A reliable partner guarantees your designs are printed with high quality and great care.

For a seamless experience and professional results, you can directly print with us at CA. Our dedicated platform simplifies the entire process for you.

At CustomAny, you just need to follow these simple steps to get your stickers made:

- Choose the type you want to print

- Select the size and quantity you want

- Upload your completed design file

- Review the digital proof

- After you approve the proof, wait for production and shipping.

For a more detailed process, explore our complete guide on “How to make custom stickers with CustomAny” to turn your creativity into real stickers.