Blog

The Superiority of UV DTF Transfer Stickers from CustomAny

Transfer stickers are increasingly known in the sticker printing industry due to their exceptional qualities. These stickers have no background and they can transfer design onto various surfaces.

However, not all transfer stickers are created equal. That’s where UV DTF transfer stickers from CustomAny come in. We takes these stickers to the next level by offering outstanding features. Our stickers are known for their durability, vibrant colors, and ability to withstand various weather conditions.

This article will explain detailed information about UV DTF Transfer Stickers. It will help you have a comprehensive understanding of why UV DTF transfer stickers from CustomAny are the ultimate choice for those seeking excellence and perfection in their designs.

What Are UV DTF Transfer Stickers?

Overview

What are transfer stickers, or more detailed, what are UV DTF transfer stickers?

UV DTF (Direct to Film) transfer stickers are a type of adhesive sticker that are printed using a UV printing method. This is an innovative UV sticker printing process that uses a UV printer to print directly onto film (PET film).

Production

In the production process, a UV printer is used to print the design onto a transparent film layer A using UV-curable ink. This type of ink dries instantly when exposed to UV light, resulting in a sharp and detailed print.

The printing is done in multiple layers, including an adhesive layer, a white ink layer, a colored ink layer, and a protective coating layer. This creates a raised and durable surface, enhancing the visual appeal and longevity of the sticker.

After the printing process, a transfer tape layer B is applied over the top of the printed film. This transfer tape layer allows the sticker to be easily transferred from the film to a desired surface. The transfer tape layer also provides additional protection to the printed design during the application process.

Structure

The structure of UV DTF transfer stickers typically consists of 3 layers. The bottom one is a film that works as the backing layer to hold everything together (A film). The middle layer is the printed layer, which contains the sticker design. The top layer is the transfer tape layer (B film), which facilitates the application of the sticker.

Application

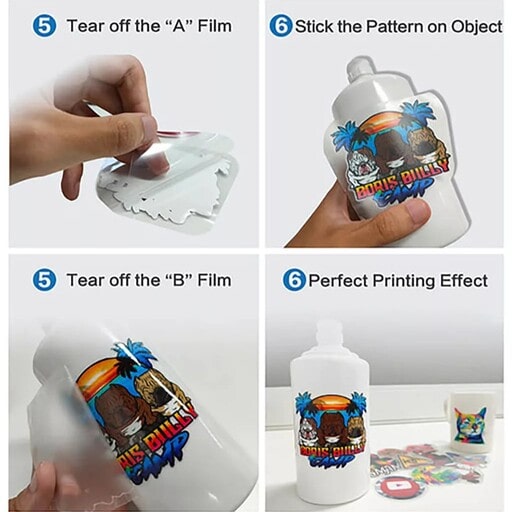

An UV DTF transfer sticker can be applied to according to these following steps:

- Peel off the bottom layer (A film)

- Apply the sticker on the object

- Rub it to firmly adhere

- Finally, slowly peel off the transfer tape layer (B film).

Why our UV DTF Transfer Stickers over standard vinyl?

Here are reasons why our UV DTF transferable stickers offer several advantages over standard vinyl transfer stickers, making them a superior choice for various applications.

Intricate details

UV DTF stickers are made entirely of UV-cured ink (not ink printed on a base layer), allowing for the creation of intricate prints with extremely fine details.

In contrast, vinyl transfer stickers are cut from a single sheet of vinyl, which can sometimes result in less sharp and detailed prints. That’s why you potentially can also not cut the vinyl stickers if they have very small or delicate details.

Full-Color Brilliance

Since UV DTF transfer stickers are printed using ink and they have no background layer, these stickers can be printed in full color. On the other hand, in case vinyl transfer stickers are cut from vinyl sheet, they will be limited in 2 colors: white or black.

Durability

UV DTF stickers have 3 layers of ink and are instantly dried using UV light, resulting in a durable and waterproof finish. They are resistant to tear and wear, making them ideal for long-lasting applications. Vinyl transfer stickers, in comparison, just consist of a single layer of vinyl. So, they are also more susceptible to tearing and wear over time.

High quality look

UV DTF stickers offer a high-quality look with their 3D raised surface effect. The multiple layers of ink create a raised surface that adds depth and dimension to the design. Furthermore, these stickers have no background, allowing the design to seamlessly blend into the surface.

In contrast, vinyl transfer stickers, although they also have no background, are typically thinner (because of 1 layer structure) and don’t create the same visual impact as the UV DTF stickers.

How CustomAny’s UV DTF transfer stickers can be used?

The versatility of UV DTF transfer stickers from CustomAny allows them to be used in various applications, adding visual impact, customization, and branding to a wide range of surfaces and products. Our recommendations are listed below for your reference:

- Promotional Materials: These stickers are commonly used for branding purposes, such as adding company logos to promotional materials, marketing campaigns, or giveaways.

- Product Packaging: They can be used to label and decorate product containers, boxes, or bags.

- Personalized Products: Our UV DTF transferable stickers are perfect for personalizing items like phone cases, mugs, water bottles, and laptop covers.

- Vehicle Decals: These stickers can be applied to vehicles, including cars, motorcycles, and bicycles, to add custom designs, logos, or messages for expressing personal views, showing love for sports teams, movie characters, etc.

- Signage: Our UV DTF transferable stickers are suitable for both indoor and outdoor signage.

- Event Decor: They can be used for weddings, parties, and exhibitions to create customized and eye-catching banners, backdrops, and event signage.

- Gift Personalization: CustomAny’s UV DTF transfer stickers are ideal for personalizing gifts (such as pens, water bottles, notebooks,…) for special occasions like birthdays, anniversaries, or holidays.

How to Order UV DTF Transfer Stickers

Ordering UV DTF transfer stickers from our website is an easy process. You just need to follow these steps:

- Visit the product page for UV DTF transfer stickers on our website.

- Choose the desired size for your stickers. We offer sizes ranging from 1-15 inches, but we recommend selecting a size of at least 3″x3″ to ensure that intricate designs with small details are accurately printed.

- Select the quantity of stickers you wish to order. Our options range from 1 to 10,000 pieces.

- Then, the system will calculate the price based on your selected size and quantity. Next, upload your design file.

- Once you have uploaded your design, click “Add to Cart”. Then, complete the necessary shipping and payment details and finalize your order.

- After you have placed your order, we will send you a soft proof via email, allowing you to review and make any necessary.

Once the printing process is completed, your order will be carefully packaged and shipped to your location.

All the products available on our website follow the same ordering process. So, if you’re interested in a more detailed explanation of how to place an order of any kind of stickers, you can find it in our blog named “How to order custom stickers from CustomAny“.

FAQs

Are UV DTF transfer stickers waterproof?

Yes, our transfer stickers are waterproof. Thanks to the use of UV curable ink and the instant drying process, the printed design on these stickers can be submerged in water and used in moist environments.

Are UV DTF transfer stickers dishwashers safe?

Yes, they are dishwasher safe. The ink material and printing technology used in these stickers make them resistant to water and scratches. So, you can wash them by hand or even in a dishwasher. However, it is recommended to avoid using hot water when cleaning them.

What are the side effects of UV DTF transfer stickers?

While UV DTF transferable stickers offer several advantages, it is important to consider some potential side effects. One challenge is their removal. These stickers can be difficult to remove once applied to a surface because of their strong adhesive.

Additionally, UV DTF stickers may have a higher cost compared to vinyl transfer stickers due to the advanced printing technology and materials used.

Related article: “What is DTF printing and How does it work?“

Can you use UV DTF for shirts?

No, it is important to note that UV DTF stickers are designed for use on sturdy, flat, and relatively smooth surfaces such as plastic, glass, and metal.

If you want to apply them to fabric, you have to use DTF printing to produce stickers with only 2 layers. Then, use heat transfer to apply to the shirt.

Is DTF and UV DTF the same?

DTF (Direct-to-Film) and UV DTF (UV Direct-to-Film) are similar in concept but utilize different printing technologies. DTF involves printing on a heat-sensitive film through pigment ink, while UV DTF utilizes UV curable ink and UV light for curing.

As mentioned above, DTF printing is a printing method used for the fabric printing industry while UV DTF printing is used for producing stickers – which are used for flat and sturdy surfaces. UV printing offers additional benefits such as instant drying, water resistance, and durability.

When should you choose to use UV DTF transfer stickers?

UV DTF transferable stickers are an excellent choice when you require intricate details, full-color printing, durability, and a high-quality look.

If you need stickers for promotional materials, product packaging, personalizing products, vehicle decals, signage, event decor, or gift personalization, UV DTF transfers can provide superior results compared to traditional vinyl stickers.

Besides, you should consider using UV DTF transferable stickers for applications that require long-lasting and visually appealing results.

Conclusion

In summary, UV DTF transfer stickers from CustomAny are the superior choice for durable, waterproof, and vibrant sticker options. Don’t miss out on the opportunity to enhance your branding and personalization efforts and experience the differences.