Blog

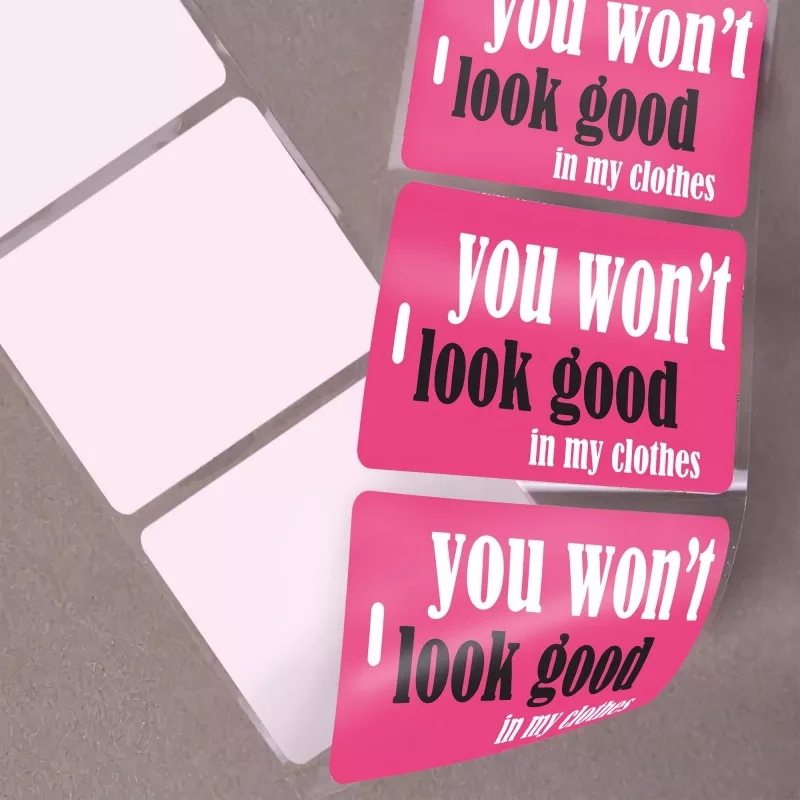

Choose flood coating or spot underprinting to make vibrant custom stickers and labels?

When it comes to creating custom stickers and labels, there are several printing techniques available, including underprinting. In the previous blog post, we discussed how underprinting can enhance the vibrancy of custom stickers and labels. Now, let’s dive deeper into the two main types of underprinting: flood coating and spot underprinting.

In this article, we will define flood coating and spot underprinting then explore the benefits and drawbacks of each method. We will also compare the two techniques in 5 important to provide you guidance on when to use flood coating or spot underprinting to achieve the best results.

What is flood coating?

Flood coating is a method of underprinting used in making custom stickers and labels. In this method, a layer of underprinted ink (commonly white) is applied to the entire surface of the material before the colored inks are added. This provides a solid base layer that can enhance the vibrancy and opacity of the colored inks

The process of flood coating can be done using a printing press or other printing equipment that is capable of applying an even layer of ink. Once the white ink has been applied, the colored inks are printed on top of it, creating a vibrant appearance.

Advantages of flood coating:

- Increased Vibrancy: As mentioned above, flood coating provides a solid base layer of white ink, allowing printed design to look more vibrant and attractive.

- Improved Opacity: Flood coating increases the opacity of the colored inks, making them more visible and easier to read.

- Suitable for Dark or Colored Materials: Flood coating is particularly useful when printing on dark or colored materials, as the underprinting provides a base layer that allows the colors to stand out.

- Professional Look: Flood coatings do nothing but enhance the overall look and quality of custom stickers and custom labels, making them look more professional and polished.

Flood coating is an effective method for enhancing stickers’ overall look and quality, especially when their pros are made use of. However, besides a lot of advantages, there are some disadvantages that you may want to consider.

Disadvantages of flood coating:

- Cost: Flood coating can be more expensive than other methods of underprinting, as it requires more ink and time to apply a layer of white ink to the entire surface of the material.

- Limited Design Flexibility: Flood coating may limit the design flexibility, as it provides complete coverage of the material with a solid layer of white ink. This may not be suitable for all design styles.

- Time-consuming: The process of flood coating somewhat is time-consuming, in some cases can affect the turnaround time for the final product.

- Ink saturation: Overuse of flood coating can lead to ink saturation, where the printed material becomes too saturated with ink, resulting in a blurry or smudged design

Overall, flood coating is an effective method but it may not be suitable for all design styles and purposes. For best guidance and recommendations on whether flood coating is the best method for your specific design and needs, feel free to contact us at [email protected].

What is spot underprinting?

In spot underprinting, white ink is applied only to specific areas of the design where it is needed.

The process of spot underprinting involves identifying the specific areas of the design that need to be enhanced with white ink. These areas are then printed with a layer of white ink before the colored inks are added. This can be done using a printing press or other printing equipment that is capable of applying ink to specific areas of the material.

Spot underprinting is specifically useful for enhancing certain elements of the design, such as text or logos, while leaving other areas of the design untouched. It is also used to create special effects, by using metallic or glossy white ink.

Spot underprinting can be an e.ffective method of underprinting when used appropriately, only when you are sure about their advantages and disadvantages.

Advantages:

- Increased Design Flexibility: Spot underprinting provides the flexibility to apply white ink only where it is needed, which can enhance specific areas of the design without affecting other areas. This allows for more intricate and detailed designs.

- Cost-effective: Spot underprinting is a cost-effective method of underprinting, as it requires less ink and time to apply white ink only to specific areas of the material.

- Special Effects: Spot underprinting can be used to create special effects, such as a metallic or glossy finish, by using the respective inks for underprinting.

- Versatility: Spot underprinting is available for a variety of materials, including both clear and colored materials.

Disadvantages:

- Limited Opacity: Spot underprinting may not provide the same level of opacity as flood coating, as it only provides coverage to specific areas of the design.

- Limited Vibrancy: Spot underprinting may not enhance the vibrancy of the colored inks as much as flood coating, as it does not provide a solid base layer of white ink.

- Time-consuming: The process of spot underprinting can be time-consuming, as it requires identifying specific areas of the design that need to be enhanced with white ink.

- Ink saturation: Overuse of spot underprinting can lead to ink saturation, where the printed material becomes too saturated with ink, resulting in a blurry or smudged design.

Flood coating vs Spot underprinting

As being said, flood coating and spot underprinting both have their own advantages and disadvantages depending on the specific needs of your design. Let’s take a closer look at five key factors to consider when comparing flood coating vs spot underprinting techniques:

1. Application

Flood coating involves applying a layer of white ink to the entire surface of the material before the colored inks are added. Spot underprinting, on the other hand, involves applying white ink only to specific areas of the design where it is needed.

2. Coverage

Flood coating provides complete coverage of the material with a solid layer of white ink, while spot underprinting provides coverage only to specific areas where it is needed.

3. Cost

For the same design, using flood coating is more expensive than using spot underprinting, as it requires more ink and time to apply a layer of white ink to the entire surface of the material.

4. Effectiveness

Flood coating and spot underprinting both enhance the vibrancy and opacity of the colored inks. However, flood coating is generally more effective in, as it provides a solid base layer for the inks to be printed on.

5. Design flexibility

Spot underprinting provides more design flexibility, as it allows for specific elements of the design to be enhanced with white ink. Flood coating, on the other hand, may limit the design flexibility due to the complete coverage of the material with white ink.

When should we use flood coating over sport underprinting, and vice versa

The decision to use flood coating or spot underprinting ultimately depends on the specific design and needs of the custom stickers and labels. Here are some general guidelines on when to use flood coating over spot underprinting and vice versa:

Choose Flood Coating over sport underprinting when:

- Printing on Dark or Colored Materials: When printing on dark or colored materials, using flood coating over spot coating for a solid layer to provide a base layer so that your design can totally stand out.

- Needing High Opacity: Applying a flood coating provides your stickers and labels a high level of opacity. This allows what you printed on them more visible and easier to read.

- Wanting Vibrant Colors: If you want a vibrant and eye-catching product, you should go for flood coating, as it enhances the vibrancy of the colored inks.

Choose Spot Underprinting ove flood coating when:

- Needing Design Flexibility: Spot underprinting provides flexibility to apply white ink only where it is needed, allowing you to make only important details to stand out.

- Wanting Special Effects: Spot underprinting is a perfect option if you want to create special effects, such as a metallic or glossy stickers.

- Cost Considerations: On a tight budget for printing custom stickers and labels? Then you should spot underprinting over flood coating your design. It is a cost effective method but gives you

Overall, choosing bettween flood coating and spot underprinting depends on your designs and purposes of use. Flood coating is an excellent choice for printing on dark or colored materials, providing high opacity, and creating vibrant colors. However, it may not be cost-effective for projects with complex designs or when only specific areas need white ink. Spot underprinting, on the other hand, offers design flexibility, special effects, and cost savings, but may not be suitable for printing on colored materials or achieving high opacity.

Conclusion

To sum up, choosing between flood coating vs spot underprinting depends on several factors, including the design, material, and budget. In general, flood coating is best for simpler designs and darker materials, while spot underprinting is better suited for complex designs and lighter materials. We at CustomAny hope that with all the information we offered you above, you have an in-depth understanding about the advantages and disadvantages of flood coating and spot underprinting, and whether to use flood coating or spot underprinting would bring the best possible results for your custom stickers and labels production.