Why Is My Sticker Cutting Not Right? 3 Tips to Prevent it

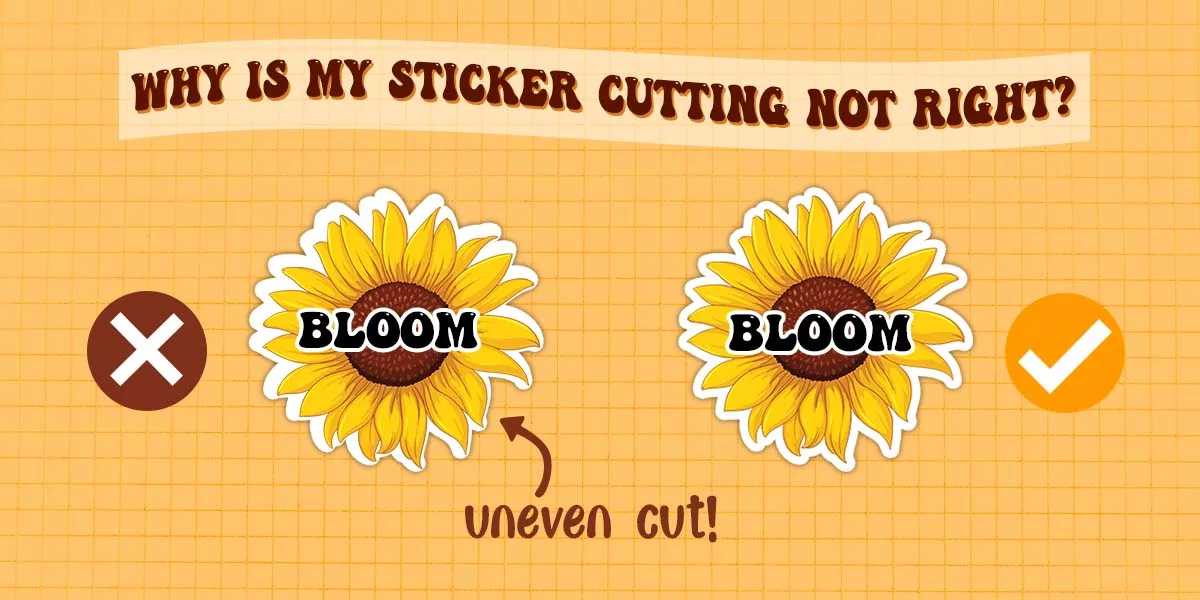

When sticker cutting isn’t done correctly, it can be a major issue. A poor cut can lead to problems with overall appearance, adhesive backing, peeling and other problems that make the final product look less professional. Inaccurate sticker cutting issues can ruin your carefully-crafted design, and it’s important to identify the cause if you want to prevent it from happening.

So, what can cause inaccurate sticker cutting? In this article, we’ll dive into why your sticker cutting may not be cut out right, provide you with tips for precise cutting, and give you a few troubleshooting techniques that may help resolve the issue. Let’s explore!

Why Is My Sticker Cutting Not Right?

Whether you’re creating custom stickers or labels, inaccurate cutting can lead to an unprofessional-looking result. So, it is important to investigate why there is an issue before attempting to fix it so that there are no further issues. Here, we will provide descriptions and explanations of common reasons behind improper sticker cutting to refine your processes for accurate sticker cutting results in the future.

1. Insufficient Bleeds

Bleeds are the extra space around the edge of your design that extends beyond the cut line. This extra space is necessary to ensure that the design is cut correctly and that there are no white edges left on the sticker after cutting.

When there is full bleed vs no bleed, the design may not be cut correctly. With full bleed, there may be white edges left on the sticker after cutting. On the other hand, if your stickers have no bleed”, the cutter may cut into the inner part of the stickers. This is because the blade of the cutting machine may not be able to cut to the edge of the design.

2. Cutting Equipment Calibration

You can choose any cutting machine you want to customize your tickers. But if you have a tight budget, we suggest a list of sticker cutters with reasonable prices and good quality here.

When cutting stickers, calibration is an important factor that ensures that your machine is cutting accurately. If the calibration is off, the blade of the cutting machine may not be able to cut all the way through the sticker material or it may cut too deep into the material. This causes the sticker to be cut incorrectly and may result in white edges being left on the sticker after cutting.

3. Inexperienced and irresponsible printing company

Another reason for inaccurate sticker cutting is the printing companies you work with are inexperienced or irresponsible. They often lack the necessary expertise or equipment to ensure that your stickers are cut correctly. It’s the possibility that they are not equipped with the proper tools to ensure that the blade is sharp and clean, or that the cutting mat is clean and free of debris.

Besides, unprofessional companies are not likely to have the necessary knowledge to adjust the blade depth or cut settings for the material you are using.

These problems cause your stickers to have improper alignment, inconsistent pressure, or lack of attention to detail.

Tips to Prevent Inaccurate Sticker Cutting

The incorrect cutting of stickers can result in unsatisfactory results and cause undue delays. According to our earlier discussion, the reasons for this problem are due to incomplete bleeds, cutting equipment calibration, or unprofessional printing companies.

To ensure these issues will not happen, there are a few fundamental steps that must be taken to prevent inaccurate sticker cutting.

1. Design File Preparation

Preparing your design files assists you in creating an image shape that is distinct and clear and corresponds to the outline you want for your sticker.

To aid the cutting machine in identifying the borders of your sticker, set your sticker on a transparent backdrop. Alternatively, you may aid the cutting process by leaving enough space for a white-cut contour line to make the sticker stand out against any backdrop and make up for any flaws.

As an added bonus, if you take the time to meticulously prepare your design file, you’ll be able to ensure that its dimensions, color mode, resolution, and bleed size all correspond to the printer and cutter’s requirements. Doing so will significantly lessen the potential for wrong sticker cutting.

You can read our “7 terrible mistakes when getting your sticker file ready for printing” blog for better preparation.

2. Equipment Maintenance

If you’re printing and cutting stickers on your own, you will meet the machine’s failures owing to moving components, such as expelled material, sharp edges, crushing, shearing, temperature, or electricity. These may all lead to inaccurate sticker cutting.

In these circumstances, regular equipment maintenance will help you avoid breakdowns, fix any issues that do occur, and keep things running smoothly.

In addition, proper maintenance of your equipment is one of the best ways to guarantee that you are in line with the standards that apply to your sticker requirements. In this way, your sticker-printing and cutting process will work more efficiently.

3. Collaborate with Printing Professionals

As mentioned above, if you are using a printing service, incorrect sticker cutting problems may occur due to an unreliable company. So, choose printing professionals, like us at CustomAny.

The experts in the printing industry can ensure that your design file is prepared with the proper dimensions, resolution, bleed, and cut line to meet all of the printing and cutting requirements. Also, they can help you choose the right materials, adhesives and finishes for your stickers that suit your design and application needs. Moreover, collaborating with them ensures your good-looking sticker production, thanks to their high-quality equipment and methods.

Addressing Inaccurate Sticker Cutting

If you use service from a printing company and end up with unacceptable cut stickers, contact them immediately to find a solution.

In the unlikely event that you have a problem with your order when using CustomAny’s printing service, please get in touch with us within 30 days of receipt.

We will conduct an inspection of the products after we have received your notification. In the event that your purchase is problematic in any way, such as being damaged or incorrectly printed, we will reproduce it for you without having you send back the original products. We promise to give you back the full value of the products you have ordered if you decide that you do not want to get replicated items and ask for a refund. In this case, take the time to go through our Return and Refund Policy if you need any more information.

However, CustomAny labor force with a high level of expertise and years of combined experience, we guarantee that the stickers we supply to you will be of the highest quality. After you have passed the “soft proof” that we will give to you through email, we are certain that these circumstances will not occur.

Conclusion

If you’re having trouble getting your sticker cutting project just right, you’re not alone. Many crafters struggle to find the right combination of tools and materials to achieve the perfect cut. However, after reading this article you would have a better understanding of why things can go wrong and how to fix them. So, hopefully, we have helped save you time and money in future projects!