The significance of accurate color reproduction cannot be ignored when it comes to sticker printing. Colors have the power to make a statement. It can be used to create an emotion, convey a message or even influence people’s opinions about your brand. For this reason, it is important to maintain color accuracy in sticker printing, especially for branding and design requirements.

In this article, we will talk about the three causes of color differences in sticker printing. We will also discuss useful tips that are essential in helping you eliminate these problems. Let’s find out!

What causes Color Differences in Sticker Printing

Quality sticker printing, although a seemingly simple printing method, can be difficult to perfect if the wrong steps are taken. Without properly examining color differences before going ahead with production, you may end up with unwanted results that could prove costly.

The wrong process of getting sticker files may be a reason. Our blog post, “7 terrible mistakes when getting your sticker file ready for printing,” might help you determine whether you’re making any of these mistakes.

Besides, color differences can be made because of many other causes. Here are a few examples of the most typical errors:

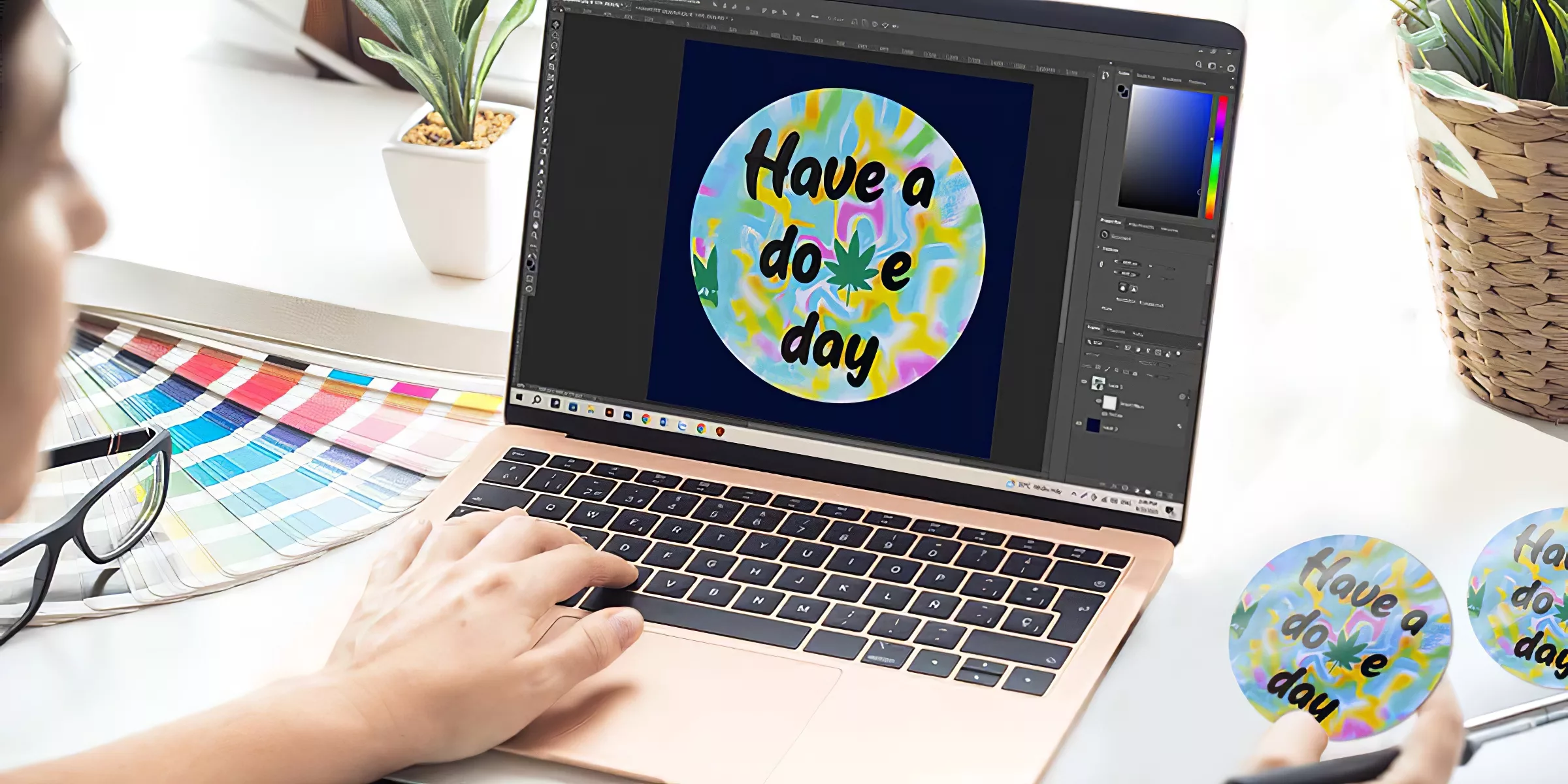

1. Monitor Calibration

Variations in monitor settings, such as brightness, contrast, and color temperature, can affect the perceived colors of the printing stickers.

Specifically, they change the way the monitor displays the colors from the source: Brightness affects the overall luminance of the display; contrast affects the difference between light and dark areas, and color temperature affects the warmth or coolness of the colors.

These settings alter the color accuracy of the monitor, which is measured by factors such as color space, color gamut, and Delta E levels. If these settings are not calibrated to match the printer output, the colors of the printing stickers may look different from what you see on your monitor.

2. Printing Technology

Different printing technologies, such as digital printing, offset printing, or screen printing, can influence color reproduction because they use different methods and materials to transfer ink onto the substrate.

Digital printing uses toner or inkjet to directly print the image onto the paper, while offset printing uses metal plates and rubber blankets to transfer the ink. Screen printing uses a mesh screen and a squeegee to push the ink through the stencil.

Different printing technologies can influence color reproduction by affecting factors such as color gamut, resolution, consistency, and special effects. Therefore, various printers will produce different colors when printing stickers, and not every reproduction will accurately suit your requirements.

3. Color Profiles

Common color profile standards, such as RGB and CMYK, are specifications that describe how colors are displayed and reproduced by different devices.

RGB stands for red, green, and blue, and it is a color model that uses additive color mixing to create colors by combining different amounts of these primary colors. RGB is suitable for display devices, such as monitors and TVs, that emit light to create colors.

CMYK stands for cyan, magenta, yellow, and black, and it is a color model that uses subtractive color mixing to create colors by removing different amounts of these primary colors from white light. CMYK is compatible with printing equipment that uses ink or toner to produce colors on paper or other surfaces.

Therefore, different printing color standards can influence printed sticker colors reproduction by affecting factors such as color range, accuracy, consistency, and compatibility. Depending on the purpose and requirements of your printing job, you may need to choose the most suitable color profile standard for your custom printed stickers.

If you want to learn more about RGB and CMYK’s differences and how to transfer between them, read our article: “Should I choose RGB vs CMYK for printing stickers?” for more details.

5 power tips for Managing Color Difference in Sticker Printing

After you explore why color differences occur in sticker design printing, the next step is to find out the solutions for these causes. Following are some of our recommended suggestions.

1. Color Management in Design

To maintain color integrity during sticker printing, you can follow some simple sticker printing tips, such as using the CMYK process color, which is the combination of primary colors (Cyan, Magenta, Yellow, and Black) to create a full-color sticker.

Additionally, you can use color calibration tools to ensure that the colors your screen displays match the colors that will be printed.

2. Seek for guidance

To manage color differences in the self-printing process, you can seek expert guidance in choosing the right printing color profiles, printing technologies, and materials. That way, you can have a firmer grasp on the principles behind color management to achieve optimal printing results. If you are looking for guidance from a professional printing expert, we at CustomAny are very honored to help. Feel free to contact us at [email protected], anytime you need, we’ll do our best to support and solve your problems.

3. Printed Color Samples for Reference

For sticker printing companies, using printed color samples for reference is ideal. This allows you to compare the colors on the various printed materials alongside the corresponding color you want and choose the sticker that best suits your project. This can ensure your sticker color control and that the colors you choose are consistent across all your printed materials.

4. Collaborating with Printing Professionals

Collaborating with printing professionals can help you manage color differences in sticker printing by providing you with expert guidance in choosing the right color profiles, printing technologies, and materials. In addition, they may instruct you on the fundamentals of color management and the best course of action to take in order to get desirable printouts.

5. Proofing

When ordering stickers from printers, it is important to reduce color difference possibilities by requesting samples or proofing stickers from the printing service collaboration. Because it helps you ensure that the colors you see on your computer screen are color matching with what will be printed on your stickers.

By requesting color proof prints or samples from the printing service, you can avoid costly mistakes and ensure that your stickers look exactly how you want them to.

Conclusion

Color variations are always a challenge when it comes to sticker printing. To get the best print results and minimize color differences, it is important to take a close-up look at the causes of these variations and take the necessary steps to eliminate them. We hope that we have provided proper knowledge on color differences during the printing process, and we hope you can be sure to avoid any color differences in any of your sticker printing projects.